Tuam Tshoj Tempered iav rau Electronic Devices

Hauj lwm lawm

Kev tsis

Qhov zoo ntawm tempered iav

- Kev nyab xeeb: Tempered iav yog suav hais tias yog iav kev nyab xeeb vim nws muaj zog thiab muaj peev xwm tawg mus rau hauv cov khoom me me, sib npaug thaum tawg. Qhov no txo qhov kev pheej hmoo ntawm kev raug mob los ntawm cov npoo ntse thiab cov shards loj, ua rau nws zoo tagnrho rau cov ntawv thov uas muaj kev nyab xeeb muaj kev txhawj xeeb, xws li hauv tsheb qhov rais, qhov rooj da dej, thiab iav partitions.

- Lub zog: Tempered iav yog qhov muaj zog dua li iav niaj hnub. Nws tau dhau los ua cov txheej txheem thermal tempering qhov twg nws tau rhuab mus rau qhov kub thiab txias sai sai, tsim kom muaj qhov compression uas ntxiv dag zog rau cov iav. Qhov no ua rau nws tiv taus kev cuam tshuam, khoov, thiab thermal stress.

- Thaum tshav kub kub kuj: Vim nws cov txheej txheem tsim khoom, tempered iav muaj qhov kub siab dua piv rau cov iav tsis tu ncua. Nws tuaj yeem tiv taus qhov kub thiab txias yam tsis muaj qhov tawg lossis tawg, ua rau nws tsim nyog rau cov ntawv thov uas muaj qhov kub thiab txias hloov pauv, xws li lub qhov rooj qhov cub, qhov cub, thiab qhov cub qhov cub.

- Durability: Cov txheej txheem tempering txhim khu lub durability ntawm tempered iav. Nws tiv taus ntau dua rau khawb, chips, thiab tawg piv rau cov iav niaj hnub. Qhov kev ua haujlwm ntev no ua kom lub neej ntev dua, txo qhov kev xav tau ntawm kev hloov pauv thiab cov nqi tu.

- Kev tiv thaiv kev tawg: Tempered iav tiv taus ntau dua rau kev tawg los ntawm kev quab yuam sab nraud piv rau cov iav niaj hnub. Nws tuaj yeem tiv taus qhov cuam tshuam ntau dua, xws li cua daj cua dub, hailstorms, lossis kev cuam tshuam tsis zoo, ua rau nws tsim nyog rau cov ntawv thov uas xav tau kom muaj zog ntxiv, xws li cov qhov rais hauv cov tsev siab lossis iav thaiv hauv cov kis las kis las.

Txheej Xaiv

AG txheej

|

|

Lub ntsej muag ntawm lub iav qub yog hloov mus rau qhov chaw diffused los ntawm tshuaj etching lossis txau. Thaum lub teeb pom kev sab nraud, nws tsim ib qho kev xav tsis thoob, uas ua rau lub teeb pom kev tsawg dua thiab ua tiav lub hom phiaj ntawm kev tshem tawm glare, txhim kho tus neeg pom qhov kev xav. |

|

|

Ib feem |

Cov ntaub ntawv |

|

|

Gloss |

40-120 |

|

|

Haze |

3-20 |

|

|

Roughness |

0.06-0.34 |

|

|

Kev xa tawm |

40-92 feem pua |

|

|

Kev puas tsuaj |

> 2500 Cycle |

|

AR Txheej

|

Nrog kev txhawb nqa ntawm magnetron-sputtering thev naus laus zis, peb tuaj yeem ua cov iav tempered nrog cov txheej txheem tiv thaiv kev cuam tshuam, txhawm rau kom txo qis kev cuam tshuam ntawm iav thaum txhim kho lub teeb pom kev zoo. Yog li cov duab tso saib yuav pom tseeb dua. |

|

|

Ib feem |

Cov ntaub ntawv |

|

|

Ib txwm Transmittance |

Ntau dua lossis sib npaug li 95 feem pua |

|

|

Kev xa tawm siab tshaj plaws |

Ntau dua lossis sib npaug li 98 feem pua |

|

|

Reflectance |

{{0}} 5-4.0 feem pua |

|

|

Scratch Resistance |

Ntau dua lossis sib npaug li 9H |

|

|

Kub Resistance |

650 degree |

|

AF Txheej

|

Raws li lub tswv yim ntawm nplooj nplooj, AF txheej txheej txheej iav 'ntws nrog ib txheej nyias ntawm nano-chemical tshuaj kom nws muaj zog hydrophobic, tiv thaiv roj, thiab tiv thaiv tus ntiv tes muaj peev xwm. Qhov saum npoo yog yooj yim dua thiab smoother. Yog li ntawd nws yooj yim dua los so cov av, cov ntiv tes, cov roj stains, thiab lwm yam ntawm cov iav nto. |

|

|

Ib feem |

Cov ntaub ntawv |

|

|

Friction Factor |

0.03-0.07 |

|

|

Kev puas tsuaj |

3000 Cycle |

|

|

Tso lub kaum sab xis |

110 |

|

|

Nto Zog |

16 MJ/M |

|

|

Rubbing |

2500 Cycle |

|

Kuj muaj nrog ITO, FTO, Antibacterial, Hydrophobic txheej

Daim ntawv thov

- Electronic Devices

- Smart Home Application

- Hnub Ci Vaj Huam Sib Luag

- Tsev

- Cov khoom siv teeb pom kev zoo

- Qhov (socket) / kov vaj huam sib luag

- Zaub Npog iav

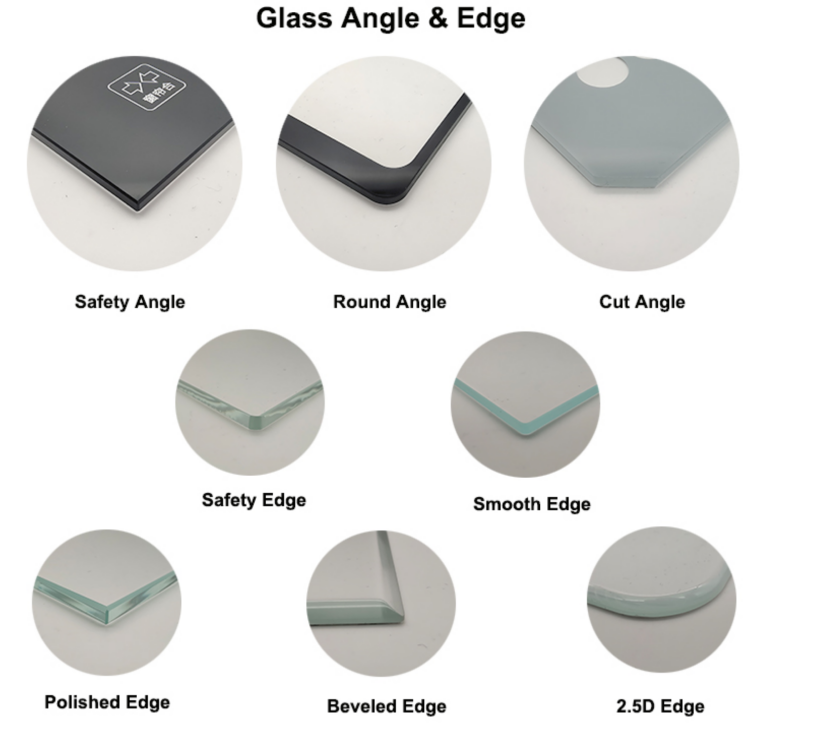

Kev kho ntug

Ua hauj lwm ib puag ncig saib xyuas

Factory Overview & Customer Visit

Tuam txhab Profile

Neeg tuaj xyuas

FAQ

Q: Yuav tsum iav tempered thiab dab tsi yog qhov txawv ntawm Chemical tempered thiab lub cev tempered?

Rau qhov me me / thickness tsawg dua 3.2mm, peb pom zootshuaj tempered.(sov toughen los ntawm 6-7H).

Kom loj dua qhov loj / tuab saum 3.2mm, peb pom zoolub cev tempered.

Raws li thermal tempered, qhov kev xeem fragmentation txheem / qhov ntau thiab tsawg & kom muaj nuj nqis tuaj yeem tsim los ntawm cov thickness sib txawv.

Lub iav flatness tuaj yeem nug tom qab tempering.

Q: Hom iav yuav siv li cas?

Teeb pom kev zooPeb feem ntau sivclear / ultra ntshiab ntab iavrau ntau lawm, nyob ntawm tus neeg siv khoom xav tau.

Npog iavPeb feem ntau sivAGC (Dragontail)rau ntau lawm, tab sis kuj muaj nyob rau hauvgorilla/NEG etc.raws li cov neeg siv khoom xav tau

Rooj tog iavPeb feem ntau sivhigh quality flat/bending iav

Q. Koj puas kam txais kev txiav txim me me?

Txhua qhov kev txiav txim kom muaj nuj nqis yog txais tos. Tab sis qee hom khoom yog tus nqi siab uas tsis haum rau kev txiav txim me me.

Q: Kuv puas tuaj yeem tau txais cov qauv thiab kuaj koj qhov Zoo?

Yog lawm. Txheeb xyuas peb cov kev muag khoom nrog cov ncauj lus kom ntxaws / Cov duab kos, lossis tsuas yog ib lub tswv yim lossis kos duab. Peb yuav xa cov qauv rau koj.

Q: Kuv yuav tsum muab dab tsi kom tau txais cov lus hais?

1. Hom iav, tuab thiab loj.

2. Kev kos duab ntawm lub khob

3. Kev xav tau hauv cov ntsiab lus.

4. Kev txiav txim kom muaj nuj nqis.

5. Lwm tus koj xav tias tsim nyog

6. Cov txheej txheem them nyiaj tshuav thiab qhia peb koj lub tswv yim ntawm kev xa khoom nyab xeeb.

7. Txaus siab rau koj qhov kev txiav txim.

Q: Koj lub tuam txhab nyob qhov twg? Qhov chaw nres nkoj nyob ze koj? Kuv tuaj yeem them nyiaj mus ntsib?

Zoo siab txais tos. Peb lub Hoobkas nyob hauv Guangdong Tuam Tshoj, ze rau Shenzhen thiab Guangzhou chaw nres nkoj. Thov qhia rau peb paub yog tias koj xav tuaj, peb yuav qhia txog kev taw qhia hauv cov ntsiab lus.

Cim npe nrov: Tuam Tshoj tempered iav rau cov khoom siv hluav taws xob, Tuam Tshoj Tuam Tshoj tempered iav rau cov khoom siv hluav taws xob manufacturers, lwm tus neeg

Kev xa khoom & Them nyiaj

Ntim:

Kauj Ruam 1: PE zaj duab xis txheej (Nquag) / ntawv (Rau seashipment tiv thaiv ntub).

Kauj ruam 2: Kraft daim ntawv rau fixation.

Kauj Ruam 3: Thawv rau iav tiv thaiv kev nyab xeeb.

Kauj Ruam 4: Kev cai ua plywood rooj plaub nrog pob khawm rau kev cai (fumigation ntxiv rau kev tshuaj xyuas yooj yim) yooj yim.

Kauj ruam 5: Packing pluaj rau fixation ntxiv.

Chaw nres nkoj

Shenzhen los yog Hongkong

Xa kev nug